Learn about the camshaft position sensor, its symptoms, diagnostic testing, replacement steps, and preventive maintenance tips for optimal engine performance.When it comes to maintaining the performance of your 5.9 Cummins engine, understanding the camshaft position sensor (CMP) is crucial. This small but vital component plays a significant role in ensuring that your engine runs smoothly, accurately timing fuel injection and ignition. Unfortunately, like any automotive element, the CMP can fail over time, leading to a variety of symptoms that can impact your vehicle’s performance. In this blog post, we’ll delve into the common signs indicating a faulty camshaft position sensor, explore diagnostic testing methods, and provide you with clear steps for replacement. Additionally, we’ll share some preventive maintenance tips to help you extend the lifespan of your sensor, ensuring your engine continues to operate at its best. Whether you’re a seasoned mechanic or a truck enthusiast, understanding these aspects can help you keep your vehicle in top shape.

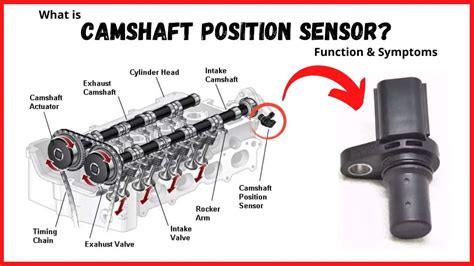

Understanding the Camshaft Position Sensor

The Camshaft Position Sensor (CMP) is a vital component in modern engines, especially in the 5.9 Cummins engine. It plays a crucial role in the engine management system by monitoring the position of the camshaft and providing real-time data to the Engine Control Module (ECM). This information is essential for optimal engine timing, fuel injection, and overall performance.

The CMP sensor works by using magnetic or hall-effect principles to detect the camshaft’s position as it rotates. This data allows the ECM to adjust various engine parameters to ensure smooth operation and efficiency. Understanding how this sensor functions can help in diagnosing potential issues that may arise.

Importance of the Camshaft Position Sensor

1. Timing Accuracy: The CMP sensor ensures accurate timing of the engine’s valves, which is critical for performance.

2. Fuel Efficiency: By communicating precise camshaft position data, the sensor helps optimize fuel injection, leading to improved mileage.

3. Emission Control: A properly functioning CMP sensor aids in reducing exhaust emissions, making your engine more environmentally friendly.

How It Works

The operation of the camshaft position sensor can be summed up as follows:

- Detection: The sensor detects the camshaft position based on notches or teeth on the camshaft gear.

- Signal Transmission: It sends a signal to the ECM indicating the exact position of the camshaft.

- Adjustment: The ECM processes this data and adjusts the timing accordingly for optimal performance.

In essence, maintaining the functionality of the camshaft position sensor is crucial for preserving engine performance and preventing more severe engine-related issues down the road.

Common Symptoms of a Faulty Sensor

The camshaft position sensor is a crucial component in your vehicle’s engine management system, particularly in a 5.9 Cummins engine. When this sensor malfunctions, it can lead to various performance issues. Here are some common symptoms that indicate a faulty camshaft position sensor:

| Symptom | Description |

|---|---|

| Check Engine Light | One of the first signs of a problem is the illumination of the check engine light on your dashboard. This can signal various issues, including a malfunctioning camshaft position sensor. |

| Engine Misfires | If the camshaft position sensor fails, it can cause the engine to misfire or run roughly, leading to poor performance and possibly damaging other engine components. |

| Difficulty Starting | A faulty sensor may lead to starting difficulties, as the engine control unit requires accurate camshaft position data for optimal ignition timing. |

| Reduced Power | Drivers may notice a pronounced loss of power, especially during acceleration, as the engine struggles to perform efficiently. |

| Stalling Engine | In some cases, the engine may stall while driving, which can be hazardous, especially in busy traffic conditions. |

If you experience any of these symptoms, it’s vital to have your camshaft position sensor checked. Ignoring these signs can lead to more severe engine issues and costly repairs.

The performance of your vehicle heavily relies on the accuracy of the camshaft position sensor. Don’t underestimate its role!

Diagnostic Testing for Camshaft Position Sensor

Testing the camshaft position sensor is a critical diagnostic step when encountering engine performance issues. A malfunctioning sensor can lead to poor engine performance, decreased fuel efficiency, and even stalling. Here’s how to effectively test the camshaft position sensor:

Tools You Will Need:

- Multimeter

- OBD-II Scanner

- Screwdriver Set

- Safety Glasses

- Owner’s Manual (for location and specifications)

Steps to Diagnose the Camshaft Position Sensor:

- Visual Inspection:

Begin with a thorough visual inspection of the sensor and its wiring. Check for:

- Frayed or damaged wires

- Corrosion on electrical connectors

- Any signs of physical damage to the sensor

- Use an OBD-II Scanner:

Connect an OBD-II scanner to the vehicle’s diagnostic port. Check for any trouble codes related to the camshaft position sensor, such as:

- P0340: Camshaft Position Sensor Circuit Malfunction

- P0341: Camshaft Position Sensor Range/Performance Problem

- Testing Voltage and Signal Output:

Using a multimeter, measure the voltage at the sensor connector. You should typically see around 5 volts. Follow these steps:

- Turn the ignition to the On position without starting the engine.

- Probe the signal wire to measure voltage.

- If the voltage is low or absent, this indicates a faulty sensor or wiring issue.

- Check Pulse Signal:

With the engine running, use the multimeter to measure the frequency of the sensor’s signal output. You should see a changing voltage pattern corresponding to the RPM of the engine. If the pattern is erratic or nonexistent, the sensor may be faulty.

- Compare Results:

If available, compare your readings with those specified in the vehicle’s service manual to confirm they fall within the normal range.

Final Thoughts:

By following these diagnostic steps, you can determine whether your camshaft position sensor is functioning properly or needs replacing. Keeping your vehicle well-maintained helps prevent issues related to this critical component. If problems persist after testing, consult a professional mechanic for further diagnosis.

Steps to Replace a Faulty Sensor

Replacing a faulty camshaft position sensor is a crucial maintenance task that can significantly affect your vehicle’s performance. Here are the steps to guide you through the replacement process:

- Gather Required Tools and Parts:

- New camshaft position sensor

- Screwdrivers (flathead and Phillips)

- Socket wrench set

- Torque wrench

- Wire brush

- Technical service manual (for specifications)

- Ensure Safety:

Before starting, make sure to park the vehicle on a level surface, turn off the engine, and disconnect the negative battery terminal to prevent any accidental electrical shorts.

- Locate the Camshaft Position Sensor:

The camshaft position sensor is usually located near the camshaft or in the engine block. Refer to your technical service manual for the exact location on your specific engine type, such as the 5.9 Cummins.

- Remove the Old Sensor:

- Disconnect the wiring harness from the sensor.

- Use the appropriate socket or wrench to remove the mounting bolts securing the camshaft position sensor.

- Carefully pull the old sensor out, noting its orientation for proper installation of the new one.

- Clean the Sensor Mounting Area:

Use a wire brush to clean any debris or corrosion from the sensor mounting area to ensure a secure fit for the new sensor.

- Install the New Sensor:

- Insert the new camshaft position sensor into the mounting area, ensuring it is aligned correctly.

- Secure it with the mounting bolts, tightening them to the specifications provided in your technical service manual.

- Reconnect the wiring harness to the new sensor.

- Reconnect the Battery:

After the installation is complete, reconnect the negative battery terminal. This restores power to the vehicle.

- Test the New Sensor:

Start the engine and monitor its performance. Check for any error codes or check engine lights. It may also be useful to use an OBD-II scanner to ensure the new sensor is functioning correctly.

By following these steps, you can successfully replace a faulty camshaft position sensor, leading to improved engine performance and reliability. Remember to consult your vehicle’s manual for any specific instructions relating to your model.

Preventive Maintenance for Camshaft Position Sensor

The camshaft position sensor plays a crucial role in the proper functioning of your vehicle’s engine. Maintaining this component is vital to ensure its longevity and efficiency. Here are some effective preventive maintenance tips to keep your camshaft position sensor in optimal condition:

- Regular Inspections: Schedule periodic checks of your engine components, including the camshaft position sensor. Look for any visible signs of wear or damage.

- Stay Clean: Keep the area around the camshaft position sensor clean and free from dirt and grime. Debris can interfere with sensor performance.

- Check Electrical Connections: Inspect the wiring and connectors associated with the camshaft position sensor. Ensure they are secure and free from corrosion.

- Routine Oil Changes: Regular oil changes can prevent harmful deposits from building up in the engine, which can affect sensor performance.

- Use Quality Parts: When replacing or servicing components linked to the camshaft position sensor, always use high-quality replacement parts to ensure compatibility and reliability.

By following these preventive maintenance practices, you can significantly extend the life of your camshaft position sensor and maintain the overall performance of your engine.

An ounce of prevention is worth a pound of cure. — Benjamin Franklin

Frequently Asked Questions

What is a camshaft position sensor and its function in a 5.9 Cummins engine?

The camshaft position sensor monitors the position of the camshaft in relation to the crankshaft, helping the engine control module ensure proper timing of fuel injection and ignition.

What are the common symptoms of a failing camshaft position sensor in a 5.9 Cummins engine?

Common symptoms include rough idling, misfiring, difficulty starting the engine, decreased fuel efficiency, and the check engine light illuminating.

How can a faulty camshaft position sensor affect engine performance?

A faulty sensor can lead to incorrect timing of the engine’s processes, resulting in poor performance, reduced power, and potentially damaging other engine components.

How can you diagnose camshaft position sensor issues in a 5.9 Cummins engine?

Diagnosis can be performed using an OBD-II scanner to check for error codes related to the camshaft position sensor, along with visual inspection of the sensor and wiring for damage.

Can a camshaft position sensor be replaced easily by a DIY mechanic?

Yes, if you have some mechanical experience, replacing the camshaft position sensor is relatively straightforward; however, it may require specialized tools and knowledge of engine components.

What are the potential causes of a camshaft position sensor failing in a 5.9 Cummins engine?

Potential causes include exposure to heat, oil leaks, electrical issues, or physical damage from wear and tear.

Is it safe to drive a 5.9 Cummins with a faulty camshaft position sensor?

It’s not advisable to drive with a faulty camshaft position sensor, as it can lead to further engine damage and compromise your vehicle’s safety and reliability.