Learn about camshaft position sensors, signs of failure, testing methods, and replacement tips to ensure optimal engine performance and reliability.The 6.0 Powerstroke engine, renowned for its performance and durability, relies on various components to operate efficiently, with the camshaft position sensor playing a pivotal role. This small yet crucial device monitors the positioning of the camshaft, ensuring precise timing for optimal engine operation. When this sensor malfunctions, it can lead to a host of performance issues, making it essential for every Powerstroke owner to understand its function and signs of failure. In this blog post, we will explore what a camshaft position sensor is, identify the telltale signs of a faulty sensor, discuss its importance, guide you on how to test it, and provide steps for replacement. Whether you’re a seasoned mechanic or a DIY enthusiast, this comprehensive guide will equip you with the knowledge needed to keep your engine running smoothly.

What is a camshaft position sensor?

The camshaft position sensor is a crucial component in an engine’s ignition and fuel injection systems. Its primary function is to monitor the position of the camshaft and relay this information to the engine control unit (ECU). This helps the ECU make necessary adjustments to the timing of fuel injection and ignition, ensuring optimal engine performance.

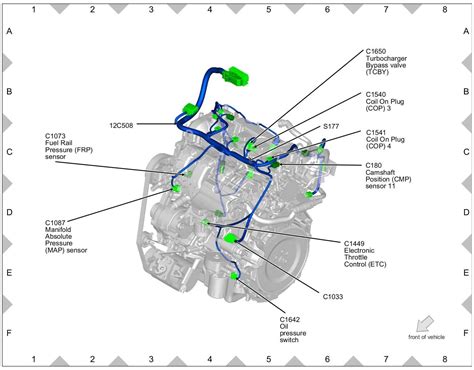

Typically located near the camshaft, the sensor uses either magnetic or Hall-effect technology to detect the position of the camshaft and signal the ECU. This data is vital for maintaining the proper synchronization between the crankshaft and camshaft, which is essential for smooth engine operation.

In diesel engines like the 6.0 Powerstroke, the camshaft position sensor plays an even more significant role. It helps to control several crucial functions, including:

- Timing of the injection events

- Fuel atomization

- Engine stability and efficiency

When the camshaft position sensor is functioning correctly, it contributes to better fuel efficiency and lower emissions. However, if it fails or provides inaccurate readings, it can lead to a series of problems including rough idle, reduced power, or even failure to start.

Overall, understanding the role of the camshaft position sensor can help car owners maintain their vehicles better and address potential issues before they lead to more significant problems.

Signs of a faulty camshaft sensor

The camshaft position sensor plays a critical role in the engine management system by providing information about the camshaft’s position to the engine control unit (ECU). When the sensor starts to fail, it can lead to various issues that can affect your vehicle’s performance. Here are some common signs indicating a faulty camshaft position sensor:

| Sign | Description |

|---|---|

| Check Engine Light | If the camshaft position sensor is malfunctioning, the check engine light may illuminate on your dashboard. A diagnostic scan can confirm if the sensor is the issue. |

| Engine Misfires | Misfires can occur due to incorrect timing information sent by a faulty sensor, leading to uneven engine operation. |

| Difficulty Starting the Engine | A defective sensor may cause issues with starting the engine, as the ECU struggles to spark the ignition at the right time. |

| Poor Acceleration | If your vehicle is hesitating or lagging during acceleration, this can be a result of a faulty camshaft position sensor. |

| Increased Fuel Consumption | A malfunctioning sensor can lead to incorrect fuel injection, causing the engine to consume more fuel than necessary. |

It’s important to be aware of these signs, as ignoring them may lead to further engine problems. If you suspect your camshaft position sensor is failing, it’s advisable to consult a professional mechanic to diagnose and address the issue.

Importance of the camshaft sensor

The camshaft position sensor plays a critical role in the overall performance and efficiency of your vehicle’s engine, especially in a high-performance engine like the 6.0 Powerstroke. This sensor is primarily responsible for detecting the position of the camshaft, which is essential for the proper timing of the engine’s operations. Here are some key points that highlight the importance of the camshaft sensor:

- Engine Timing: The camshaft position sensor ensures that the engine’s timing is synchronized accurately. This synchronization is crucial for optimal performance and prevents engine knock.

- Fuel Efficiency: A properly functioning sensor helps in adjusting the fuel injection timing, leading to better fuel efficiency and reducing emissions.

- Engine Performance: The sensor directly impacts how well the engine performs by regulating the timing of valve openings and closings. This can significantly affect acceleration and overall driving experience.

- Diagnostics: The camshaft position sensor contributes to on-board diagnostics, allowing the vehicle’s computer to identify potential issues early. This proactive approach can save you from costly repairs later.

- Prevention of Damage: By detecting misfires or timing issues, the sensor helps in preventing potential damage to the engine components by ensuring everything operates smoothly.

In summary, the importance of the camshaft position sensor cannot be overstated. It is a vital component that ensures not only the engine’s performance but also its longevity. Regular checks and maintenance of this sensor can lead to a smoother and more efficient driving experience.

How to test the camshaft sensor

Testing the camshaft position sensor is essential to ensure that your engine is operating smoothly, especially in high-performance applications like the 6.0 Powerstroke engine. A faulty sensor can lead to serious performance issues, including rough idling, poor fuel economy, and even engine misfires. Here’s a simple guide on how to test this crucial component.

What You Will Need:

- Digital multimeter

- Wrench set

- Service manual for the vehicle

- Safety goggles and gloves

Steps to Test the Camshaft Sensor:

- Locate the Sensor:Find the camshaft position sensor on your 6.0 Powerstroke engine, typically located near the engine’s timing cover.

- Disconnect the Sensor:Using the wrench set, carefully disconnect the wire harness from the camshaft position sensor.

- Set the Multimeter:Turn on your digital multimeter and set it to measure voltage.

- Test Voltage:With the ignition switch in the “on” position (but engine off), probe the electrical connector to check for voltage. You should see approximately 5 volts. If you don’t, there may be an issue with the wiring or the Engine Control Module (ECM).

- Check the Sensor Resistance:Switch the multimeter to measure resistance (ohms). Connect the probes to the terminals on the sensor. Refer to your service manual for the specific resistance values for your camshaft position sensor. A reading outside of those values indicates a faulty sensor.

- Reconnect and Test:Reconnect the sensor, start the engine, and monitor the engine’s performance. If issues continues, replacement may be necessary.

Important Notes:

Always consult your vehicle’s service manual to verify specifications and procedures, as testing procedures can vary slightly between different models and years.

Performing these tests helps to pinpoint whether your camshaft position sensor is in good working condition or needs replacement. Regular maintenance checks can prevent more severe issues in the long run.

Replacing the camshaft position sensor

Replacing the camshaft position sensor is a crucial maintenance task for the 6.0 Powerstroke engine that can improve the overall performance and reliability of your vehicle. Below is a detailed guide to help you understand the steps involved in the replacement process.

Tools and Materials Needed

- Ratchet and socket set

- Torque wrench

- Replacement camshaft position sensor

- Safety glasses

- Mechanic gloves

Steps to Replace the Camshaft Position Sensor

- Safety First: Before starting, ensure that the engine is cool and disconnect the negative battery terminal to prevent electrical shock.

- Locate the Sensor: On the 6.0 Powerstroke engine, the camshaft position sensor is usually located at the front of the engine, near the timing cover.

- Remove the Old Sensor:

- Unscrew any bolts holding the sensor in place.

- Gently pull the sensor out, being careful not to damage surrounding components.

- Install the New Sensor:

- Position the new camshaft position sensor into place and secure it with the original bolts.

- Ensure the sensor is seated correctly and tighten the bolts to the manufacturer’s specifications using a torque wrench.

- Reconnect the Battery: Reattach the negative battery terminal once the new sensor is installed securely.

- Test the Engine: Start the engine and monitor its performance. Check for any warning lights on the dashboard, and listen for unusual sounds.

Final Tips

When replacing the camshaft position sensor, always refer to your vehicle’s service manual for specific instructions and specifications. If you’re unfamiliar with mechanical repairs, consider consulting with a professional mechanic to ensure proper installation.

By following these steps, you can successfully replace the camshaft position sensor in your 6.0 Powerstroke, enhancing your engine’s performance and avoiding potential issues related to a malfunctioning sensor.

Frequently Asked Questions

What is a camshaft position sensor?

The camshaft position sensor is an electronic component that provides information about the position of the camshaft to the engine control unit (ECU), which helps in optimizing engine timing and performance.

Why is the camshaft position sensor important for a 6.0 Powerstroke engine?

In a 6.0 Powerstroke engine, the camshaft position sensor is vital for maintaining proper timing between the camshaft and crankshaft, which ensures smooth engine operation and optimal performance.

What are common symptoms of a faulty camshaft position sensor?

Common symptoms of a faulty camshaft position sensor in a 6.0 Powerstroke include rough idling, engine misfires, poor fuel economy, and difficulty starting the engine.

How can I diagnose a malfunctioning camshaft position sensor?

To diagnose a malfunctioning camshaft position sensor, you can use an OBD-II scanner to check for error codes, perform a visual inspection of the sensor and wiring, and test the voltage and resistance of the sensor itself.

How do I replace the camshaft position sensor in a 6.0 Powerstroke?

To replace the camshaft position sensor in a 6.0 Powerstroke, you should first disconnect the battery, remove any components obstructing access to the sensor, disconnect the electrical connector, unscrew the sensor, and replace it with a new one, followed by reassembly.

Can a bad camshaft position sensor cause engine problems?

Yes, a bad camshaft position sensor can lead to various engine problems, including stalling, reduced power, and increased emissions due to improper fuel injection timing.

How frequently should the camshaft position sensor be checked or replaced?

While there is no specific service interval for replacing the camshaft position sensor, it’s good practice to inspect it during routine maintenance or if you experience any symptoms of failure, especially if the vehicle has high mileage.