Learn about camshaft position sensors, their symptoms, diagnostic methods, replacement steps, and tips for preventing future failures. Keep your engine running smoothly!The 6.0 Powerstroke engine is a robust powerhouse, but like any complex machine, it can experience issues that affect its performance. One critical component that plays a vital role in engine functionality is the camshaft position sensor. When this sensor fails or begins to malfunction, it can lead to a cascade of symptoms that can hinder the engine’s efficiency and responsiveness. In this blog post, we will delve into the intricacies of the camshaft position sensor, explore the common symptoms that indicate a faulty sensor, and guide you through diagnosing and replacing it. Moreover, we’ll discuss preventive measures to help you avoid future sensor failures, ensuring your Powerstroke runs smoothly for years to come. Whether you’re a seasoned mechanic or a curious truck owner, this guide will provide valuable insights to keep your engine in peak condition.

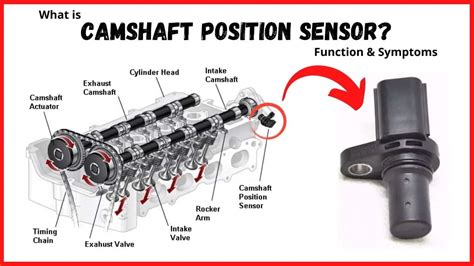

Understanding the Camshaft Position Sensor

The camshaft position sensor is a critical component in your vehicle’s engine management system, particularly in modern vehicles like the 6.0 Powerstroke. This sensor helps the engine control unit (ECU) monitor the position and speed of the camshaft, enabling the proper timing of fuel injection and ignition. Understanding how this sensor works and its significance can be crucial for maintaining your vehicle’s performance.

How It Works

The camshaft position sensor operates based on detecting the position of the camshaft lobes. It provides real-time data to the ECU about the camshaft’s position, which is essential for synchronizing the crankshaft and camshaft. This synchronization is vital for the proper functioning of the engine, impacting everything from fuel efficiency to engine power and emissions.

Types of Camshaft Position Sensors

- Magnetic Sensor: Uses magnetic fields to detect the position of the camshaft.

- Hall Effect Sensor: Employs a semiconductor to sense the position via magnetic fields.

- Optical Sensor: Uses light to determine the camshaft positioning.

Importance of the Camshaft Position Sensor

The functionality of the camshaft position sensor directly influences several critical engine operations:

- Engine Timing: Accurate data from the sensor ensures proper timing for fuel injection and ignition.

- Engine Efficiency: Helps optimize fuel usage, leading to better fuel economy.

- Emissions Control: A healthy sensor contributes to reducing harmful emissions.

Common Issues Related to the Camshaft Position Sensor

Over time, the sensor can develop faults which may lead to significant engine issues. Recognizing the symptoms of a failing sensor can help you address problems before they escalate.

In summary, the camshaft position sensor plays a crucial role in the overall operation of your engine. Understanding its function and importance can help you maintain your 6.0 Powerstroke in peak condition.

Common Symptoms of a Faulty Sensor

The camshaft position sensor plays a crucial role in ensuring that the engine runs smoothly and efficiently. When this sensor fails or starts showing faults, it can lead to various performance issues in the 6.0 Powerstroke engine. Here are some of the most common symptoms that indicate a faulty camshaft position sensor:

- Check Engine Light: One of the first signs of a problem with the camshaft position sensor is the illumination of the check engine light on the dashboard. This light can stem from various issues, but it’s essential to have the sensor checked as a primary step.

- Engine Misfires: If the camshaft position sensor is malfunctioning, it may send incorrect timing data to the engine control module (ECM), causing misfires. Drivers may feel their vehicle shuddering or stuttering during acceleration.

- Rough Idle: A faulty sensor can disrupt the normal timing of fuel injection and ignition, leading to a rough or unstable idle. If you notice your engine vibrating excessively while at a stop, this could be a sign of a sensor issue.

- Difficulty Starting: If the camshaft position sensor doesn’t provide accurate readings, it can lead to starting difficulties. This can manifest as the engine cranking but not starting, or taking longer than usual to start.

- Decreased Fuel Efficiency: A failing camshaft position sensor can cause improper fuel delivery, leading to increased fuel consumption. If you notice your fuel efficiency dropping unexpectedly, it might be worth checking the sensor.

- Unusual Engine Noise: A malfunctioning camshaft position sensor might result in abnormal engine noises due to timing issues. This can include knocking, popping, or excessive vibration.

Recognizing these symptoms early on can help mitigate further damage to your vehicle’s engine system. If any of these signs are present, it is advisable to conduct a thorough diagnosis or seek professional assistance.

Diagnosing the Issue with a Sensor

Diagnosing a faulty Camshaft Position Sensor (CMP) is a crucial step in ensuring your vehicle runs smoothly, especially for the 6.0 Powerstroke engine. The CMP is vital for timing the engine’s fuel injection and ignition systems, and any malfunction can lead to a cascade of performance issues.

Common Diagnostic Steps

- Check Engine Light: One of the first indicators of a faulty CMP is the appearance of the check engine light on your dashboard. Use an OBD-II scanner to retrieve any trouble codes, particularly the P0340 or P0344, which often relate to camshaft position issues.

- Visual Inspection: Examine the wiring and connectors leading to the sensor. Look for signs of corrosion, fraying, or other physical damage that might cause interruptions in the sensor’s function.

- Sensor Voltage Test: Using a multimeter, check the voltages from the sensor when the engine is running. Typical voltage should be within specified ranges (consult the vehicle’s service manual). A significant deviation can indicate a problem.

Symptoms to Consider

Here are some symptoms that may arise if the camshaft position sensor is failing:

| Symptom | Description |

|---|---|

| Rough Idling | The engine may struggle to maintain a smooth idle, resulting in vibrations and oscillation. |

| Decreased Power | There may be an overall loss of engine power, making acceleration sluggish. |

| Stalling | The engine might stall unexpectedly, which could be hazardous while driving. |

| Difficulty Starting | The vehicle may have trouble starting if the sensor isn’t providing accurate information to the engine control unit. |

Utilizing Advanced Diagnostics

If initial checks and visual inspections don’t yield clear answers, consider using advanced diagnostic tools:

Utilizing an oscilloscope can reveal waveform patterns from the sensor, allowing for a more thorough diagnosis of its performance under different conditions.

In some cases, especially with complex engine issues, consulting a professional mechanic may be necessary to accurately diagnose and resolve problems related to the Camshaft Position Sensor. Remember that prom

Replacing the Camshaft Position Sensor

Replacing a camshaft position sensor can be an important task in maintaining your vehicle’s performance. The camshaft position sensor plays a critical role in the engine management system, helping to ensure that the engine runs smoothly and efficiently. If you’ve diagnosed a faulty sensor, here’s how to go about replacing it.

Tools and Materials Needed

- Socket set

- Screwdrivers

- Replacement camshaft position sensor

- Torque wrench

- Rags or shop towels

- Safety glasses

Step-by-Step Guide to Replacing the Sensor

- Safety First: Always start by ensuring the engine is off and cool. Disconnect the battery to avoid any electrical shorts.

- Locate the Camshaft Position Sensor: The location of the sensor can vary based on the vehicle model, but it is commonly found near the camshaft or at the back of the engine. Refer to your vehicle’s manual for precise location details.

- Remove Electrical Connectors: Carefully disconnect the electrical connectors from the old sensor. Use a flathead screwdriver if necessary to gently pry them apart.

- Unscrew the Sensor: Use the appropriate socket to remove the bolts that secure the camshaft position sensor in place. Set them aside as you will need them for the new sensor.

- Remove the Old Sensor: Lift the old sensor out, ensuring no debris falls into the engine. Clean the area around the sensor to prevent contamination.

- Install the New Sensor: Place the new camshaft position sensor into the same position as the old one. Align it carefully and secure it with the screws.

- Reconnect Electrical Connectors: Plug in the electrical connectors to the new sensor, ensuring they are securely attached.

- Reconnect the Battery: Once everything is installed, reconnect the battery terminals.

- Test the Engine: Start the engine and let it run for a few minutes. Monitor for any error codes or warning lights that may indicate a problem.

Tips for a Successful Replacement

Always follow the manufacturer’s guidelines for specific torque settings and procedures when replacing the camshaft position sensor.

By following these steps, you can successfully replace the camshaft position sensor and restore your vehicle’s performance. Regular maintenance and timely replacements can help prevent future issues and keep your engine running smoothly.

Preventing Future Sensor Failures

When it comes to the 6.0 Powerstroke camshaft position sensor, understanding how to prevent future sensor failures can save you from costly repairs and prolonged engine issues. Here are some proactive measures you can take:

- Regular Maintenance: Conduct routine inspections and replace engine oil regularly to ensure the overall health of your vehicle. Clean oil helps maintain the integrity of the sensor.

- Clean Electrical Connections: Corrosion and dirt on electrical connections can impede the performance of the camshaft position sensor. Regularly check and clean these connections to ensure optimal conductivity.

- Use Quality Parts: When replacing parts, such as the camshaft position sensor, ensure you are using high-quality components that meet OEM specifications. Cheap, substandard parts are more likely to fail.

- Monitor Engine Performance: Keep an eye on any irregular performance, such as misfires or rough idling. Addressing issues early can prevent further damage to the sensor.

- Avoid Overheating: Excessive heat can damage sensors. Ensure your cooling system is working efficiently and promptly address any overheating issues.

By staying proactive and adopting these strategies, you can significantly lower the risk of future camshaft position sensor failures and keep your 6.0 Powerstroke running smoothly.

Frequently Asked Questions

What is a camshaft position sensor and what role does it play in a 6.0 Powerstroke engine?

The camshaft position sensor in a 6.0 Powerstroke engine monitors the position of the camshaft and sends this information to the engine control module (ECM). It helps the ECM adjust fuel injection timing and ignition timing for optimal engine performance.

What are some common symptoms of a faulty camshaft position sensor in a 6.0 Powerstroke?

Common symptoms of a faulty camshaft position sensor in a 6.0 Powerstroke include rough idling, poor fuel economy, difficulty starting the engine, and unexpected stalling.

Can a malfunctioning camshaft position sensor affect the performance of a 6.0 Powerstroke engine?

Yes, a malfunctioning camshaft position sensor can lead to erratic fuel injection and ignition timing, causing reduced engine performance, increased emissions, and potential long-term engine damage.

How can you diagnose a bad camshaft position sensor in a 6.0 Powerstroke engine?

To diagnose a bad camshaft position sensor, you can use an OBD-II scanner to check for related trouble codes, inspect the sensor and wiring for damage, and monitor the engine’s performance while looking for symptoms.

What steps should I take if I suspect my camshaft position sensor is failing?

If you suspect that your camshaft position sensor is failing, start by checking for error codes using an OBD-II scanner. If codes related to the sensor appear, consider replacing it. Additionally, inspect related wiring and connectors for any signs of wear or damage.

Is it safe to drive a 6.0 Powerstroke with a bad camshaft position sensor?

While it may be possible to drive with a bad camshaft position sensor, it is not recommended. Doing so can lead to reduced performance, stalling, or even further damage to the engine if left unaddressed.

What is the typical cost for replacing a camshaft position sensor in a 6.0 Powerstroke?

The cost of replacing a camshaft position sensor in a 6.0 Powerstroke can vary depending on labor rates and parts costs, but it generally ranges from $100 to $300, including both parts and labor.