Learn the significance of the camshaft position sensor bolt, how to find and measure the correct size, source a replacement, and ensure proper installation.When it comes to maintaining your vehicle’s engine performance, the camshaft position sensor plays a crucial role in monitoring the position of the camshaft and syncing it with the crankshaft. However, ensuring that this sensor is securely fastened is just as important, and that’s where understanding camshaft position sensor bolt size comes into play. Using the correct bolt size not only facilitates proper alignment and functionality but also prevents potential engine malfunction. In this blog post, we’ll delve into the significance of the camshaft position sensor bolt, guide you through finding the correct bolt size, and provide tips on measuring existing bolts and sourcing reliable replacements. Additionally, we’ll share essential installation practices to ensure that your sensor operates optimally. Whether you’re a seasoned mechanic or a DIY enthusiast, this guide will equip you with the knowledge you need to keep your engine running smoothly.

Importance of Camshaft Position Sensor Bolt

The camshaft position sensor bolt plays a vital role in the operation of your vehicle’s engine management system. This small yet significant component is responsible for securing the camshaft position sensor in place, ensuring that it functions correctly. Here are a few key reasons highlighting the importance of this bolt:

- Secure Connection: The bolt ensures that the camshaft position sensor is tightly fastened, preventing any movement that could affect sensor readings.

- Accurate Sensor Functionality: A well-secured sensor will provide accurate data to the engine control unit (ECU), which is crucial for optimal engine performance.

- Prevention of Damage: A loose or improperly installed bolt can lead to sensor misalignment, increasing the risk of damage to the sensor or other components.

- Improved Engine Efficiency: By maintaining the position of the camshaft position sensor, the vehicle can achieve better timing and coordination between the camshaft and crankshaft, enhancing overall engine efficiency.

- Cost-Effective Maintenance: Regularly checking the condition of the camshaft position sensor bolt can prevent expensive repairs caused by sensor failure. A small investment in proper bolt maintenance can save considerable costs in the long run.

In summary, the camshaft position sensor bolt may be a small component, but its significance in maintaining engine health and performance cannot be overstated. Ensuring that it is correctly sized and properly installed is essential for a smooth and efficient driving experience.

Finding the Correct Bolt Size

When it comes to the maintenance of your vehicle, the camshaft position sensor bolt is often an overlooked component. However, selecting the correct bolt size is crucial for ensuring the proper functioning of the camshaft sensor, which directly affects engine performance. In this section, we will discuss the steps you need to take to find the right size for your camshaft position sensor bolt.

1. Understand the Specifications

Before you start measuring or sourcing a replacement, make sure to refer to your vehicle’s service manual for the specifications. These manuals typically provide comprehensive information regarding:

- Thread size (for example, M6, M8)

- Bolt length (how long the bolt needs to be)

- Material type (steel, aluminum, etc.)

2. Measuring the Existing Bolt

If you have access to the existing bolt, measuring it can be one of the easiest ways to find the correct size. Use a caliper or a measuring tape to determine:

- Diameter: Measure the diameter across the threads.

- Length: Measure the length of the bolt from under the head to the tip.

- Thread pitch: Count the number of threads per inch (or millimeter) to determine the thread pitch.

3. Sourcing the Replacement Bolt

Once you have the correct measurements, you can source the replacement bolt from auto parts stores or online suppliers. Look for:

- Parts specifically designed for your vehicle make and model.

- High-quality materials to ensure longevity and reliability.

4. Tips for Choosing the Right Size

Here are some additional tips to keep in mind when selecting the camshaft position sensor bolt size:

Never compromise on quality. A cheap, inferior bolt can lead to engine damage.

- Check compatibility: Make sure the bolt fits snugly without being too tight.

- Consider torque specifications: Follow the manufacturer’s recommended torque settings during installation.

By following these steps, you can ensure that you find the correct bolt size for your camshaft position sensor, ultimately leading to better engine performance and reliability.

Measuring the Existing Bolt

When replacing the camshaft position sensor bolt, one of the crucial steps is accurately measuring the existing bolt. This ensures that you source the correct replacement part that fits perfectly in your vehicle’s engine. Here’s how to go about it:

Tools You Will Need

- Tape Measure or Caliper: For precise measurements.

- Socket Set: To remove the existing bolt if needed.

- Thread Gauge: To determine the thread pitch.

Measuring the Length

To measure the length of the camshaft position sensor bolt, follow these steps:

- Remove the bolt using a socket wrench.

- Use a caliper or ruler to measure the total length of the bolt from tip to head.

- Sometimes, the length you need is the effective length once installed; if so, measure it with the washers or spacers in place.

Measuring the Diameter

Next, you need to measure the diameter of the bolt:

- Take a caliper and measure the thickness across the widest part of the bolt thread.

- Ensure to check for any variations if the threads are slightly worn.

Determining the Thread Pitch

The thread pitch is essential for ensuring compatibility with the new bolt:

- Use a thread gauge to measure the distance between threads. This will tell you how many threads are present in an inch or millimeter.

- If you don’t have a thread gauge, you can compare it with a new bolt to determine the matching pitch.

Documenting Your Measurements

Once you have gathered all necessary measurements, document them for reference:

| Measurement Type | Value |

|---|---|

| Length | [Your Measurement] |

| Diameter | [Your Measurement] |

| Thread Pitch | [Your Measurement] |

By carefully measuring the existing camshaft position sensor bolt, you will ensure that you have the correct specifications needed for a proper fit, thus preventing any potential engine issues.

Sourcing the Replacement Bolt

When it comes to maintaining your vehicle’s engine, finding the right camshaft position sensor bolt is crucial. After measuring the existing bolt and determining the correct size, the next step is sourcing a replacement bolt. In this process, there are a few key considerations to keep in mind:

- Material: Depending on the engine and environment, choose a bolt made from the right material. Common options include steel, stainless steel, and even titanium for certain applications.

- Tensile Strength: Ensure the bolt has adequate tensile strength to withstand the engine’s operating conditions. Look for bolts rated with a high yield point.

- Coating: A corrosion-resistant coating can enhance the lifespan of the bolt, especially in harsh environments, so consider whether a coating is necessary.

- Compatibility: Always check that the replacement bolt is compatible with your specific make and model of vehicle.

Once you’ve determined the necessary specifications, the next step is to find a reliable source for your replacement bolt. Here are a few options:

| Source | Description |

|---|---|

| Automotive Parts Stores | Local or chain stores often stock common bolts. Always verify that you have the right size. |

| Online Retailers | Websites like Amazon or specialized auto part retailers can have a broader selection. |

| Dealerships | OEM bolts can be sourced from your vehicle’s dealership, ensuring perfect compatibility. |

| Junkyards | A cost-effective option, you may find used bolts that are still in great condition. |

As you explore these options, make sure to compare prices and check reviews for quality assurance. Remember, using the right camshaft position sensor bolt not only ensures proper functionality but also contributes to the overall health of your engine.

Ensuring Proper Installation

When it comes to replacing a camshaft position sensor bolt, ensuring proper installation is crucial for optimal engine performance. Below are some key points to consider to guarantee that your installation is successful:

- Clean the Area: Before installing the new bolt, make sure to clean the area around the camshaft position sensor. Remove any debris, old sealant, or oil that may hinder the installation process.

- Use the Right Tools: Always use the right tools that are compatible with the bolt size and type. A torque wrench is essential to ensure that the bolt is tightened to the manufacturer’s specifications.

- Check for Alignment: Carefully align the camshaft position sensor and its mounting points before tightening the bolt. Misalignment can lead to improper sensor function and potential engine issues.

- Follow Torque Specifications: Refer to your vehicle’s service manual for the proper torque specifications for the camshaft position sensor bolt. Over-tightening or under-tightening can damage the sensor or lead to leaks.

- Inspect After Installation: Once the installation is complete, perform a visual inspection of the area. Look for any signs of leaks or loose connections. If possible, run the engine for a brief period to ensure that everything is functioning correctly.

A properly installed camshaft position sensor bolt can make a significant difference in the performance and longevity of your engine.

By paying close attention to these details, you can ensure that your new camshaft position sensor bolt is installed correctly, thus maintaining the efficiency and reliability of your vehicle’s engine.

Frequently Asked Questions

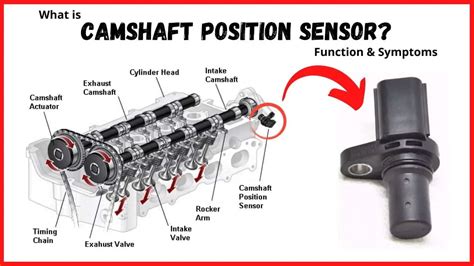

What is a camshaft position sensor?

A camshaft position sensor is an automotive sensor that monitors the position of the camshaft, providing information to the engine control unit (ECU) for proper timing and fuel injection.

Why is the camshaft position sensor important?

The camshaft position sensor plays a crucial role in ensuring the engine runs smoothly and efficiently. It helps in timing the ignition and fuel injection, impacting engine performance and emissions.

Where is the camshaft position sensor typically located?

The camshaft position sensor is usually located near the top of the engine, near the camshaft itself, often near the valve cover.

What tools do I need to replace a camshaft position sensor?

To replace a camshaft position sensor, you generally need a socket set, wrenches, and possibly a torque wrench. Depending on the vehicle, you might also need a screwdriver and a wire brush.

What is the standard bolt size for a camshaft position sensor?

The bolt size for a camshaft position sensor can vary by vehicle make and model, but it is commonly around 10mm or M6 size bolts.

Can I replace the camshaft position sensor myself?

Yes, replacing the camshaft position sensor is a task many DIY enthusiasts can handle, provided they have basic mechanical knowledge and the right tools.

What signs indicate that the camshaft position sensor might be failing?

Symptoms of a failing camshaft position sensor include engine misfires, difficulty starting the engine, poor fuel efficiency, and triggering the check engine light.