Learn how to test a fuel tank pressure sensor effectively, from selecting equipment to analyzing results for optimal vehicle performance.Testing a fuel tank pressure sensor is a crucial step in maintaining your vehicle’s performance and ensuring efficient fuel delivery. A malfunctioning sensor can lead to poor fuel economy, increased emissions, and difficulty in diagnosing other engine issues, making it essential for vehicle owners and enthusiasts alike to understand its function. In this blog post, we will delve into the intricacies of fuel tank pressure sensors, guiding you through the process of testing them effectively. From selecting the right tools and preparing your vehicle to conducting the test and interpreting the results, we’ll provide you with a comprehensive roadmap. Whether you’re a seasoned mechanic or a DIY novice, our step-by-step approach will empower you to tackle this task with confidence and precision. Let’s get started on ensuring your vehicle runs smoothly and efficiently!

Understanding the fuel tank pressure sensor

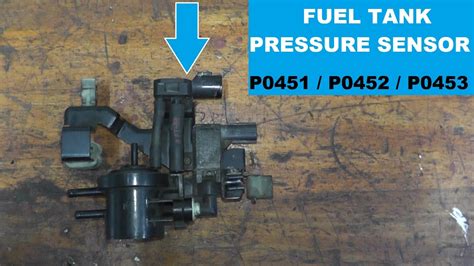

The fuel tank pressure sensor (FTP sensor) is a critical component in modern vehicles that helps monitor the vapor pressure inside the fuel tank. By ensuring that the fuel system is sealed, this sensor plays a vital role in reducing harmful emissions and improving engine performance. Understanding how it operates is essential for effective diagnostics and repairs.

The primary function of the FTP sensor is to monitor the pressure levels within the fuel tank. It sends this information to the engine control unit (ECU), which then adjusts the fuel mixture accordingly. If the sensor detects a pressure change, it can prompt the ECU to trigger various systems in the engine, including the fuel pump and the evaporative emission control system (EVAP).

How It Works

The fuel tank pressure sensor typically operates using the following principles:

- Pressure Measurement: The sensor utilizes a diaphragm that responds to pressure changes within the tank.

- Electrical Signal: As the diaphragm moves, it generates a voltage signal that is proportional to the pressure detected.

- Data Transmission: This voltage signal is transmitted to the ECU, which interprets the data for further fuel management.

Types of Fuel Tank Pressure Sensors

There are mainly two types of fuel tank pressure sensors:

Analog Sensors: These sensors provide a continuous voltage signal based on the pressure level.

Digital Sensors: These sensors send a binary signal (on/off) based on specific pressure thresholds.

Symptoms of a Failing FTP Sensor

When the fuel tank pressure sensor fails, you may notice the following symptoms:

- Check engine light illumination

- Increased fuel consumption

- Rough idling or stalling

- Failure of emissions tests

Understanding the functionality of the fuel tank pressure sensor helps in diagnosing potential issues and deciding whether a test is required or if replacement is necessary. Monitoring pressure levels can lead to better emissions control and optimized engine performance.

Choosing the right testing equipment

When it comes to testing a fuel tank pressure sensor, selecting the appropriate testing equipment is critical for achieving accurate and reliable results. Here is a list of essential tools that can be helpful in the process:

- OBD-II Scanner: An OBD-II scanner is essential for reading diagnostic trouble codes (DTCs) related to the fuel tank pressure sensor. This device can reveal if there are any significant issues affecting the sensor’s performance.

- Fuel Pressure Gauge: A fuel pressure gauge allows you to check the fuel pressure in the system, ensuring that the fuel delivery is not part of the problem.

- Vacuum Pump: This tool can help you create a vacuum in the fuel tank, enabling you to observe how the fuel tank pressure sensor responds under varying pressure conditions.

- Multimeter: A digital multimeter is crucial for measuring voltage, resistance, and continuity in the wiring and connections leading to the fuel tank pressure sensor.

- Manifold Gauge Set: For more advanced testing, a manifold gauge set can be used to monitor the pressure and vacuum levels in the fuel system.

Before starting your tests, ensure that your tools are calibrated and in good working condition. Using reliable and accurate equipment will provide you with the best results and will help you to diagnose any issues with confidence.

“The right tool for the right job is not just a saying; it’s essential for accurate diagnostics.”

Preparing the vehicle for testing

Before conducting a test on the fuel tank pressure sensor, it’s essential to properly prepare the vehicle to ensure accurate and reliable results. The preparation process can be broken down into several key steps:

- Locate the Fuel Tank Pressure Sensor: Typically, this sensor is found near the fuel tank or on the fuel pump module. Refer to the vehicle’s service manual for specific locations.

- Inspect the Vehicle: Start by visually inspecting the surrounding area of the sensor for any signs of damage or corrosion. Ensure that all connections and wiring are intact.

- Check for Codes: Use an OBD-II scanner to check if there are any diagnostic trouble codes (DTCs) related to the fuel tank pressure sensor. This can provide insight into potential issues before you begin your testing.

- Ensure Safety Precautions: Since you will be working near the fuel system, it’s crucial to follow safety measures. Turn off the vehicle and allow it to cool down. Keep a fire extinguisher nearby and work in a well-ventilated area.

- Prepare the Testing Equipment: Familiarize yourself with the testing equipment you’ll be using. Ensure that it is in good working condition and calibrated as necessary.

- Disconnect the Battery: To prevent any electrical issues or accidental shorts, disconnect the negative terminal of the battery.

- Access the Sensor: Depending on your vehicle, you may need to remove components to gain access to the fuel tank pressure sensor. Proceed with caution to avoid damaging any parts.

By following these preparation steps diligently, you will ensure a smoother testing process for the fuel tank pressure sensor, leading to accurate results and the identification of any issues more effectively.

Conducting the pressure sensor test

Once you have prepared your vehicle and selected the appropriate testing equipment, it’s time to conduct the pressure sensor test. This process is crucial for ensuring that your fuel tank pressure sensor is operating correctly. Follow the steps below to carry out the test effectively.

Required Tools

- Multimeter

- Fuel tank pressure tester

- Vehicle diagnostics tool (if applicable)

- Wrenches and screwdrivers

Step-by-Step Testing Procedure

- Ensure Safety: Before starting the test, make sure the vehicle is parked in a well-ventilated area. Turn off the ignition and disconnect the battery to avoid any electrical hazards.

- Locate the Pressure Sensor: Refer to your vehicle’s service manual to find the specific location of the fuel tank pressure sensor.

- Connect the Multimeter: Set the multimeter to measure voltage. Connect the multimeter leads to the pressure sensor terminals. Ensure that you have a good connection to garner accurate readings.

- Activate the Ignition: Turn the ignition key to the on position without starting the engine. This action should power up the fuel system.

- Measure Voltage: Observe the voltage reading on the multimeter. A healthy fuel tank pressure sensor should typically display a voltage between 0.5V and 4.5V. If the reading is outside this range, the sensor may be faulty.

- Utilize a Fuel Tank Pressure Tester: Connect the fuel tank pressure tester to the fuel tank’s pressure port. The tester will evaluate the pressure that the sensor is meant to detect.

- Check Pressure Readings: Compare the readings from the tester with the expected values listed in your vehicle’s service manual. A significant discrepancy may indicate that the sensor is not responding correctly.

Interpreting the Results

If your voltage reading and pressure readings fall within the specified ranges, the sensor is functioning correctly. However, if either of the readings is out of range, you may need to consider replacing the sensor or further investigating wiring issues or other components of the fuel system.

Troubleshooting Tips

Double-check all connections and wires leading to the pressure sensor to make sure there are no shorts or breaks that could be causing problems.

By following these steps, you can effectively conduct a pressure sensor test and determine the health of your fuel tank pressure sensor.

Analyzing the test results and next steps

After conducting a fuel tank pressure sensor test, the analysis of the results is crucial for determining the health of the sensor and the overall integrity of the vehicle’s fuel system. Understanding how to interpret these results will help you decide the next steps in your diagnostic process.

Interpreting Test Results

When analyzing your test results, keep in mind the following:

- Pressure Readings: Observe the pressure readings during the test. The readings should align with the manufacturer’s specifications. If they are too high or too low, it often indicates a sensor malfunction or issues within the fuel tank system.

- Response Time: A healthy fuel tank pressure sensor should respond quickly to changes in fuel pressure. If there is a significant delay or inconsistency in the readings, the sensor may be faulty.

- Voltage and Ground Checks: Confirm that the sensor is receiving adequate voltage and has a good ground connection. A drop in voltage or poor grounding can lead to erroneous readings.

Common Issues Identified

Some common issues that may arise during your test include:

| Issue | Possible Causes | Next Steps |

|---|---|---|

| Low pressure reading | Vacuum leaks, sensor failure | Inspect for leaks and test sensor functionality |

| High pressure reading | Fuel system blockage, faulty sensor | Check for blockages and review sensor operation |

| No reading | Electrical issues, broken sensor | Inspect wiring and replace sensor if needed |

Next Steps

Once you have interpreted your results, you can take the following next steps:

- Repair or Replace: If the sensor is determined to be faulty after thorough testing, it should be replaced with a new unit. Always use OEM parts for best results.

- Inspect Fuel Tank System: If the pressure readings indicate issues beyond the sensor, conduct a comprehensive inspection of the fuel tank and its components.

- Clear Diagnostic Codes: After making repairs, ensure to reset any diagnostic trouble codes (DTCs) using an OBD-II scanner to clear the system for accurate future tests.

- Re-Test: After repairs and inspections, conduct the test again to confirm that the issues have been resolved and the fuel tank pressure sensor functions correctly.

By following these guidelines for analyzing test results and deciding on the next steps, you can ensure your vehicle’s fuel system operates efficiently and effectively.

Frequently Asked Questions

What is a fuel tank pressure sensor?

A fuel tank pressure sensor is a component that measures the pressure within the fuel tank to ensure the fuel system is working correctly and to monitor the evaporative emissions.

Why is it important to test a fuel tank pressure sensor?

Testing a fuel tank pressure sensor is crucial because a malfunctioning sensor can lead to poor fuel economy, increased emissions, and issues with the vehicle’s performance.

What tools do I need to test a fuel tank pressure sensor?

To test a fuel tank pressure sensor, you typically need a multimeter, a fuel pressure gauge, and possibly a scan tool to read error codes.

What are the steps to test a fuel tank pressure sensor?

First, ensure the vehicle is off and the key is removed. Then, locate the sensor, check the wiring for damage, connect the multimeter, and measure the voltage output while activating the vehicle’s ignition.

How can I interpret the readings from the fuel tank pressure sensor?

Refer to the vehicle’s service manual to understand the expected voltage range. Any significant deviation from this range could indicate a faulty sensor.

What are common symptoms of a faulty fuel tank pressure sensor?

Common symptoms include illuminated check engine lights, reduced fuel efficiency, difficulty starting, and erroneous fuel gauge readings.

Can I replace the fuel tank pressure sensor myself?

Yes, if you’re comfortable with basic vehicle maintenance and have the right tools, you can replace the fuel tank pressure sensor. Otherwise, it’s best to consult a professional mechanic.