Discover the function, design, importance, and common issues of reluctor wheels in engines and camshaft sensors for optimal performance.When it comes to optimizing engine performance, the role of various components cannot be overstated. One such crucial component is the reluctor wheel, particularly in relation to the camshaft position sensor. But what exactly is a reluctor wheel, and how does it impact engine functionality? In this blog post, we delve into the intricacies of the reluctor wheel, exploring its design, construction, and vital importance in a camshaft sensor system. We’ll also discuss the common issues that can arise with reluctor wheels and how these can affect overall engine performance. Whether you’re an automotive enthusiast or simply looking to understand more about your vehicle’s mechanics, this exploration will provide valuable insights into this essential engine component.

What is a reluctor wheel?

A reluctor wheel, often referred to in the context of engine technology, is a crucial component in modern vehicles. It plays a significant role in sensing engine position and is commonly found in various automotive sensors, particularly the camshaft position sensor and crankshaft position sensor.

The reluctor wheel typically consists of a series of alternating magnetic poles, which are aligned around a circular disc. As the wheel rotates, it passes by a magnetic sensor, generating a varying magnetic field. This variation in the magnetic field is essential for determining the position of engine components.

Here’s a simple illustration of how a reluctor wheel works:

| Component | Function |

|---|---|

| Reluctor Wheel | Generates a varying magnetic field |

| Magnetic Sensor | Receives signal from the reluctor wheel |

| Engine Control Unit (ECU) | Processes the signals for engine timing |

In summary, the reluctor wheel is integral to the function of the engine management system. By providing precise signals related to the position of the camshaft or crankshaft, it enables the engine control unit to effectively manage fuel injection and ignition timing, leading to improved engine performance and efficiency.

Role of reluctor wheel in engine

The reluctor wheel, also known as the tone wheel, plays a crucial role in the functioning of modern internal combustion engines. It is a component that is instrumental in determining the position of the camshaft, which is essential for proper engine timing. Let’s delve into the specific functions of the reluctor wheel in the engine’s performance:

- Timing Accuracy: The reluctor wheel is designed with strategically placed teeth or slots that create a magnetic field when passing by the camshaft position sensor. This interaction helps to accurately determine the position of the camshaft, which is vital for timing the injection of fuel and the opening/closing of the valves.

- Signal Generation: As the reluctor wheel rotates with the engine, it passes the sensor, generating electrical pulses. These pulses are translated into signals that inform the engine control unit (ECU) about the exact position of the camshaft, allowing for optimal timing adjustments during various engine speeds.

- Enhanced Engine Efficiency: A properly functioning reluctor wheel ensures that the engine operates at peak efficiency. By providing accurate camshaft position data to the ECU, the reluctor wheel enables precise control over fuel injection and ignition timing, leading to enhanced fuel economy and reduced emissions.

- Synchronization with Crankshaft: The reluctor wheel works in conjunction with the crankshaft position sensor. Together, they provide a complete picture of the engine’s timing. The ECU uses this information to synchronize the engine’s various functions, ensuring smooth operation.

In summary, the role of the reluctor wheel in an engine cannot be overstated. It is essential for timing accuracy, signal generation, engine efficiency, and overall synchronization of the engine’s functions. Without it, the engine would struggle to perform optimally, leading to poor performance and increased wear over time.

Design and construction of reluctor wheel

The reluctor wheel, also known as the notch wheel or trigger wheel, is a vital component in modern automotive engine systems. It is primarily used in conjunction with the camshaft position sensor and plays a significant role in engine timing. Understanding its design and construction can give insights into its functionality and importance.

Design Features

The design of a reluctor wheel is relatively simple yet highly effective. Here are some key features:

- Material: Reluctor wheels are typically made from steel or other metals that can be magnetized. This ensures durability and a consistent magnetic response.

- Tooth Configuration: They often have a series of teeth or notches around their circumference. The number and arrangement of these notches are tailored to ensure precise timing signals for the engine management system.

- Diameter and Thickness: The size of the reluctor wheel varies depending on the engine design and the specifications of the camshaft sensor. A larger diameter allows more notches and can result in greater resolution for the sensor.

Construction Aspects

The construction of a reluctor wheel involves several stages:

- Manufacturing: The reluctor wheel is usually manufactured through processes like stamping or machining. This method ensures that the teeth are precisely shaped and evenly spaced.

- Magnetization: After the physical construction, the wheel is magnetized. This is essential for generating the electromagnetic signals needed by the camshaft position sensor.

- Mounting Features: The reluctor wheel often includes features for secure attachment to the camshaft. This might involve a keyway, set screws, or a press-fit design.

Proper design and construction are critical because any variation in the tooth spacing or alignment can lead to inaccurate readings and, consequently, engine performance issues. The reluctor wheel must work seamlessly with the sensors to ensure that the engine management system gets accurate and timely information about the position of the camshaft.

The efficacy of a reluctor wheel is directly linked to its design precision and construction quality, making it an integral component in modern automotive applications.

Importance of reluctor wheel in camshaft sensor

The reluctor wheel plays a crucial role in ensuring the accurate operation of the camshaft position sensor. This component is essential for optimal engine performance and efficiency. Here are several key points highlighting its importance:

- Signal Generation: The reluctor wheel is designed to generate a specific signal that is interpreted by the camshaft position sensor. This signal is crucial for determining the position of the camshaft relative to the crankshaft.

- Precision Timing: Accurate timing of the camshaft is vital for fuel injection and ignition processes. The reluctor wheel helps to maintain precise synchronization, leading to smooth engine operation.

- Engine Performance: By providing the engine control unit (ECU) with accurate camshaft position data, the reluctor wheel indirectly influences engine performance, throttle response, and fuel efficiency.

- Diagnostics: The health of the reluctor wheel affects the overall functionality of the camshaft position sensor. Monitoring the signal produced can help in diagnosing problems within the engine management system.

- Durability: A well-designed reluctor wheel contributes to the long-term reliability of the camshaft position sensor, ensuring that it continues to function effectively over time.

In summary, the importance of the reluctor wheel in the operation of the camshaft position sensor cannot be overstated. It is a fundamental component that aids in achieving

Common issues with reluctor wheel

The reluctor wheel plays a critical role in the operation of the camshaft position sensor, but like any mechanical component, it can experience issues that affect performance. Here are some of the most common problems associated with the reluctor wheel:

| Issue | Description | Potential Causes |

|---|---|---|

| Misalignment | Improper alignment of the reluctor wheel can lead to inaccurate readings from the camshaft position sensor, causing engine performance issues. | Installation errors or wear over time. |

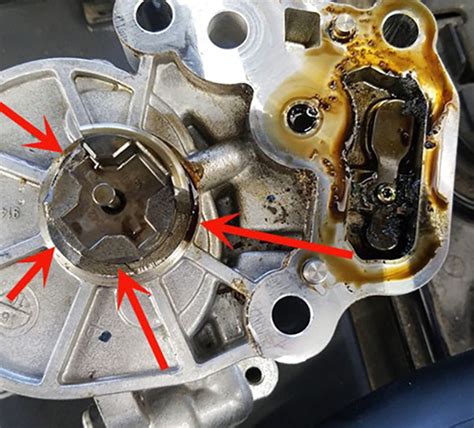

| Cracks or Damage | Physical damage to the reluctor wheel, such as cracks or chips, can result in missed signals and engine misfires. | Impact damage or manufacturing defects. |

| Corrosion | Rust and corrosion can accumulate on the reluctor wheel, affecting its ability to communicate proper position data. | Exposure to moisture or harsh chemicals. |

| Debris Buildup | Accumulation of dirt and debris can interfere with the clear passage of magnetic signals from the reluctor wheel. | Lack of regular maintenance or failing other engine components. |

| Improper Gap Setting | Inconsistencies in the gap between the reluctor wheel and the sensor can lead to unreliable readings. | Incorrect installation or wear in other engine components. |

Regular maintenance and prompt attention to any signs of trouble can help mitigate these issues, ensuring the camshaft position sensor functions correctly and the engine runs smoothly. If you suspect problems with your reluctor wheel, it’s advisable to consult a professional mechanic to assess and resolve the situation.

Frequently Asked Questions

What is a reluctor wheel?

A reluctor wheel is a component used in various automotive sensors, including the camshaft position sensor, to produce a varying magnetic field to generate a signal.

How does the reluctor wheel function in relation to the camshaft position sensor?

The reluctor wheel, attached to the camshaft, generates pulses as it rotates. These pulses are detected by the camshaft position sensor, which interprets the information to determine the position of the camshaft.

Why is the camshaft position sensor important in an engine?

The camshaft position sensor is crucial for engine timing and synchronization, allowing the engine control unit (ECU) to optimize fuel injection and ignition timing for performance and efficiency.

What symptoms might indicate a faulty reluctor wheel?

Symptoms of a faulty reluctor wheel may include engine misfires, poor acceleration, stalling, or difficulty starting the engine due to incorrect timing signals.

Can a reluctor wheel be replaced easily?

Replacing a reluctor wheel can vary in difficulty depending on the vehicle’s make and model. It typically requires access to the camshaft, so it may be best performed by a professional mechanic.

What materials are reluctor wheels typically made from?

Reluctor wheels are mostly made from ferromagnetic materials, often high-quality steel or iron, to enhance the magnetic field interactions necessary for accurate sensor readings.

How can I diagnose issues with the camshaft position sensor related to the reluctor wheel?

To diagnose issues, you can check for error codes using an OBD-II scanner, inspect the sensor for physical damage, and test the reluctor wheel’s alignment and integrity as part of a comprehensive engine diagnostic.